So during my search on web, I found this useful steps UV to etching procedure. Gladly to share with my students for these useful method.

Before you start you will need these things:

Protective gloves

Safety glasses

Preferably a gas-mask.

A CAD program

A printer

OH-paper (Transparent paper)

A UV-light

Pre-sensitized copper board (positive photoresist)

Caustic Soda

hydrochloric acid (~30%)

hydrogen peroxide (~17%)

First of you’ll need to make the layout you will be transferring to your copper board in a CAD program. I use CadSoft’s Eagle software, which I find easy to use.

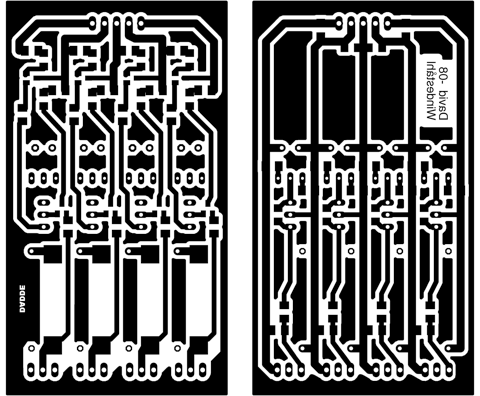

A screenshot of a high current A123 balancer in progress

When you are done with the layout it’s time to save it as a black and white image. The white areas is where the copper will be etched away.

Here is the same high current balancer layout ready for the printer.

Now it’s time to print your layout. But don’t print it on the OH-paper to begin with! Start of printing it on plain paper so see the results. You want as a dense black that is simply possible. This is important! The copies cant be better than the original that they came from. The UV-light must not be able to reach the areas of the copper that you want to have left. Also check so that all the components fit where they should fit, so that nothing have gone wrong in the printing process nor in the design process. Now you can print you layout on an OH-paper.

Here is a LED dimmer circuit printed on a OH-paper

Next step is to expose the copper board and to do that you need a UV-light source. I built myself a “UV exposure box” that uses two 8W fluorescent UV lamps with 50 mm spacing between them and 55 mm to the glass.

Take care when dealing with UV-light so that you don’t harm your eyes. Keep the lid of the box closed at all times when the lights are on.

The exposure times varies greatly depending on your setup. My setup requires 1 minute 50 seconds to achieve that perfect result.

A tip when trying to determine the right exposure time for your setup is to make test PCB. Simply cover all but one piece of the PCB with a thick paper and expose it for 1 minute and then move the paper a bit and expose it for 1 minute again, and so on. The final strip will then be exposed for 1 minute and you will have a board with 1 minute resolution witch makes it easy to get into the right ballpark at least.

When you are done with the exposure its time to develop the PCB. Now it’s time to put on the protective gloves and mix some caustic soda with water. You need 3 dl cold water and 1 teaspoon of caustic soda. Make sure that you mix it properly! The caustic soda should be completely de solved in the water.

Now place the developed PCB into the solution. There will be a fast reaction and the water will darken with the exposed photoresist. Its important that you keep a good flow on the solution around the PCB during this process either by stirring or tilting the container back and forth. As soon as it seems nothing is happening its time to get the PCB out of the solution and wash it of in cold water. This process usually takes 10-20 seconds.

(The PCB in the picture has already been washed)

Always ware gloves when using chemicals!

You will now be able to see a faint outline of the layout on the copper.

Now comes the nasty stuff!

Its time to mix the hydrochloric acid, hydrogen peroxide with water. One extremely important thing when doing this is AAA! Always Add Acid to water!NEVER EVER the other way around!

A good mix of the chemicals is 2:1:1 (2 parts water, 1 part hydrogen peroxide and 1 part hydrochloric acid). I usually mix so that I get 2 dl of solution. That means 1 dl water and 0,5 dl hydrochloric acid and 0,5 dl hydrogen peroxide. Start with the water and then add the acids! When mixing the chemicals toxic gas will be released! Be sure to be in a well ventilated area and keep your face away. If you have a gas-mask and safety glasses I strongly recommend using them during both the mixing and the etching.

Now that you have a solution that is capable of dissolving copper its time to put in the developed PCB.

Again it’s important to keep a constant flow of the solution. If you are making a double sided PCB make sure to turn it over often. After a while you will see the copper starting to disappear and the solution will turn green-blueish. Take the PCB out of the solution as soon as all the unwanted copper is dissolved and wash it in cold water.

You now have a printed circuit board!

Drill your holes and sand the copper using steal wool to get rid of the photo-resist.

The finished balancer.

Good luck with your projects!

For more reading you may go to this link rcexplorer.se

No comments:

Post a Comment